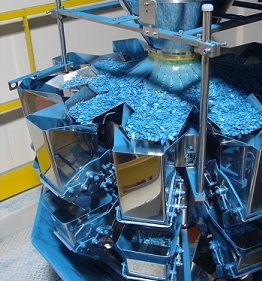

Our bag-filling machines dedicated for open mouth bags can packed on paper bags as well as plastic bags on the same line. The introduction of the bag can be manual or automatic with a bag shop of 2 or 4 stake of bags.

You can integrate a vibrator or a system to squeeze out the air of the bags before they are closed.

The production rate can go from 250 bags per hour to 650 bags per hour with all types of products.

Our system can work on Nett weight or Gross weight.and sew or weld according to the type of bag.

These bag-filling machines support bags of 5kg to 50kg. fold before sewing bag can be done before seaming, a label can be automatically stuck on the bags.

Our lines are either built with stainless steel for food application or with epoxy coated steel frame.

Automatic line EME

ACEMMA

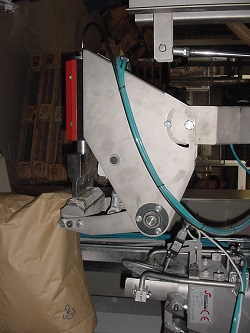

double fold bench

with adhesive

INOX bagging machine

with solder and seam

Semi-auto bagging machine

with double thread seam